WHAT IS A RSP?

Regional Sector Partnership

At its most basic, RSP is a coalition of companies in a shared industry sector, like Manufacturing, in a shared regional labor market.

How Will RSPs Help the Manufacturing Industry in Connecticut?

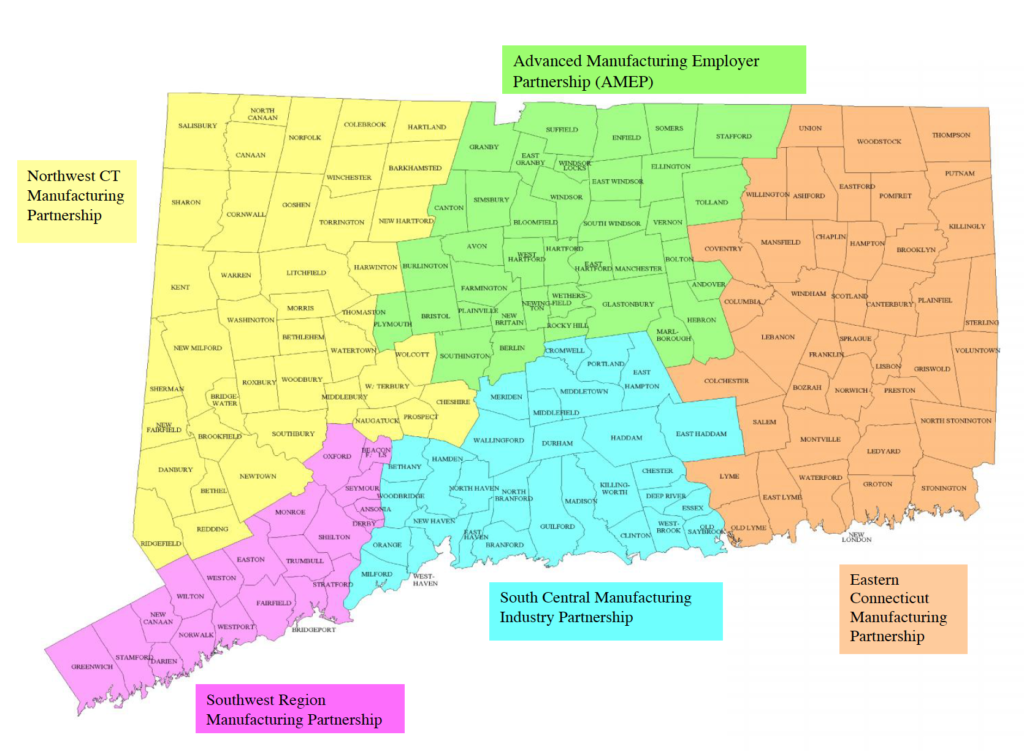

RSPs bring together C-suite business leaders from a single industry in the same region to collaborate in making their industry more competitive. They define their own agenda and tackle a range of issues including improving the workforce pipeline, improving infrastructure, or facilitating business-to-business networking. RSPs focus on issues that no single company can fully tackle on its own and that requires a collaborative approach. Most importantly, they take action at a level where they have relationships and influence and where they’ll see impact sooner than later – that’s their own backyard. That’s why in CT there are five regional Manufacturing Sector Partnerships (MSPs). These MSPs operate as coalitions, and where possible they align and leverage with statewide efforts and organizations (like ManufactureCT). CT’s RSPs are modeled after a national model of sector partnership, called Next Gen Sector Partnerships, which operate in nearly 20 states. CT is early on its RSP journey, but already making headway in organizing regionally.

Southwest Region Manufacturing Partnership

The SW Manufacturing Partnership vision is to be a network of thriving manufacturers, from the Valley to the Shore, connecting to make their region stronger for the manufacturing industry and their communities, and to mobilize as an industry sector in SW CT around shared goals and needs. The SW MP is spearheaded by Microboard, PTA Plastics, Kubtec Medical Imaging, Schwerdtle and King Industries, and since launching in June 2021 has engaged nearly 30 manufacturers. It additionally involves nearly 20 education and training partners, a half dozen Chambers of Commerce, and other government and public partners.

The SW-MP has five current areas of focus:

- Leadership and Steering (including maintaining an updated roadmap and key performance metrics focused on local hiring, worker retention, business networking, and better use of resources);

- MakeItCT, a manufacturing-driven, public sector-supported career marketing campaign targeting three audiences (students, young professionals, re-careering adults);

- Regional Hub Building, including creating an online www.makeitct.com networking space, plus executive networking, plant tours and happy hours;

- “Your Place, Your Future” Young Professional Networking, creating consistent networking opportunities between the region’s 300 manufacturers and the five young professional associations; and

- Education & Training Alignment, focused on clearly and comprehensively understanding the shared skills needs of manufacturers, prioritizing a 90-day Critical Occupation/Skills process in Spring 2022. This area of focus also includes deliberate relationship building and brokering on behalf of the SW-MRSP and the 18+ education and training secondary and post-secondary institutions with manufacturing programming in the SW CT geography.

For more information, check out www.makeitct.com or email Dan Onofrio at onofrio@brbc.org.

South Central Manufacturing Industry Partnership (SCMIP)

The South Central Manufacturing Industry Partnership launched in March 2021, spearheaded by companies like Roto Frank of America, Hobson Motzer, PennGlobe, Ulbrich Stainless Steels & Metals, and involving over 25 manufacturing execs with three shared priorities: talent, promoting manufacturing, and cost competitiveness. It is supported by three Chambers of Commerce, the regional Workforce Board and involves nearly 30 additional public and government partners. Go to https://scmipct.com/ to learn more.

- The Talent Action Team is focused on creating a talent pipeline to put the right people in the right jobs. They completed a demand survey to identify the most in-demand occupations across partnership companies and are now working to improve the alignment of educational/training/vocational programs to address the skills gaps identified.

- The Promoting Manufacturing Action Team is currently focused on promoting manufacturing careers to high school students and their parents through videos, plant tours, and career days. The Team is creating promotional videos and working to expand the list of companies in the region that are interested in holding tours and visiting schools for manufacturing awareness.

- The Competitive Cost Topography Action Team focuses on defining and addressing the cost-related issues that are an obstacle to keeping manufacturing competitive in Connecticut, with an initial focus on transportation and improving worker connectivity to manufacturing facilities around the region.

For more information, please contact Anne Benowitz at abenowitz@gnhcc.com.

Eastern Connecticut Manufacturing Partnership

The Eastern Manufacturing Regional Sector Partnership is a collaboration of ~30 state and regional stakeholders, including employers, organized labor, colleges, economic development, technical & comprehensive high schools, and others. These stakeholders identified two priorities for action: 1) Developing the Existing and Future Workforce, and 2) Cultivating Business to Business Connections. Leading companies include Collins & Jewell, Electric Boat, Web Industries, SWPC Plastics, and others.

- The Develop the Existing and Future Workforce initiative is the execution of the national-award-winning Eastern CT Manufacturing Pipeline Initiative (MPI). The MPI is a workforce program designed to raise the baseline of our labor force’s competencies to align with skills that are in demand by manufacturers. The core element of the MPI is high-rigor, skills training classes with a curriculum designed by employers and education partners. Strong engagement from employers is considered a key ingredient for program success. Since its 2016 inception, the MPI has placed 2,200+ individuals in jobs. The MPI recently was expanded to serve high school graduates via the Youth Manufacturing Pipeline Initiative (YMPI). YMPI member schools offer a 150-hour skills training curriculum to prepare graduates to enter the workforce upon graduation as opposed to college.

- The Cultivating Business to Business Connections action team seeks to develop a better understanding among manufacturers of existing programs and resources to improve. It also aims to foster a sharing of best practices and promote business development opportunities in the region including connecting local supply chains to keep businesses in Connecticut.

For more information, please contact Paul Whitescarver at SeCTer: pwhitescarver@secter.org.

Northwest CT Manufacturing Partnership

The mission of the Northwest Connecticut Manufacturing Partnership is to be a premier regional industry-led effort to promote the benefits of manufacturing careers to key target audiences, connect manufacturers to resources that can support their growth, and provide local education programs with insights on the latest industry trends and curriculum changes needed to train new manufacturing talent. The NW Manufacturing Partnership is spearheaded by Seitz, Hubbard-Hall Inc, Marion Manufacturing, Noujaim Tool and RDA Now.

- Key performance metrics of the Partnership’s collective efforts are: a substantial increase in young people choosing manufacturing as a career, a much greater proportion of local graduates choosing to stay rather than leave for manufacturing jobs outside the region, a growing number of career-changing adults choosing manufacturing, and more talent from outside our region choosing to work for local companies.

- Priority actions include a regional campaign to attract talent to manufacturing, beginning with a three-site hiring event that involved 28 local companies and resulted in the successful recruitment of new employees. The campaign continues with content (e.g., video testimonials, brochures) delivered through in-person school visits, company tours, virtual and in-person events, and social media channels.

For more information, contact Evan Berns at evanberns@comcast.net.

Advanced Manufacturing Employer Partnership (North Central/Capital Region)

The Advanced Manufacturing Employer Partnership (AMEP) is an employer-led Industry Partnership that is convened by the Connecticut Center For Advanced Technology (CCAT), Chaired by Charles Daniels of Wepco Plastics, and funded by Workforce Solutions Collaborative Metro Hartford. The focus is on the workforce needs of advanced manufacturing and technology companies in the Hartford and Enfield labor market areas which includes parts of Middlesex County.

- Vision: Every manufacturing position is filled with a qualified employee.

- Mission: AMEP will provide leadership to drive effective and efficient workforce solutions by maximizing any available resource.

Working Group Overview:

- Training Pathways – Work Group Objective: To work on and deliver best practices that help attract, employ, and retain the Advanced Manufacturing and Technology Talent Pipeline

- Job Quality –Work Group Objective: To work on and deliver best practices around supporting conversation and action toward creating an inclusive culture that makes jobs better

- Business Development–Work Group Objective: Supporting initiatives to help build manufacturing growth in the state

For more information, contact Charles Daniels at charles@wepcoplastics.com